New Product: SMC’s Mass Flow Controller for Inert Gasses

Flow control devices play an important role in maintaining precision, efficiency and reliability in semiconductor manufacturing plants — particularly when it comes to processes that involve gasses and chemicals. To help manufacturers meet these stringent requirements, SMC now offers advanced air flow controllers that manage the flow of clean, dry compressed air or nitrogen within controlled environments.

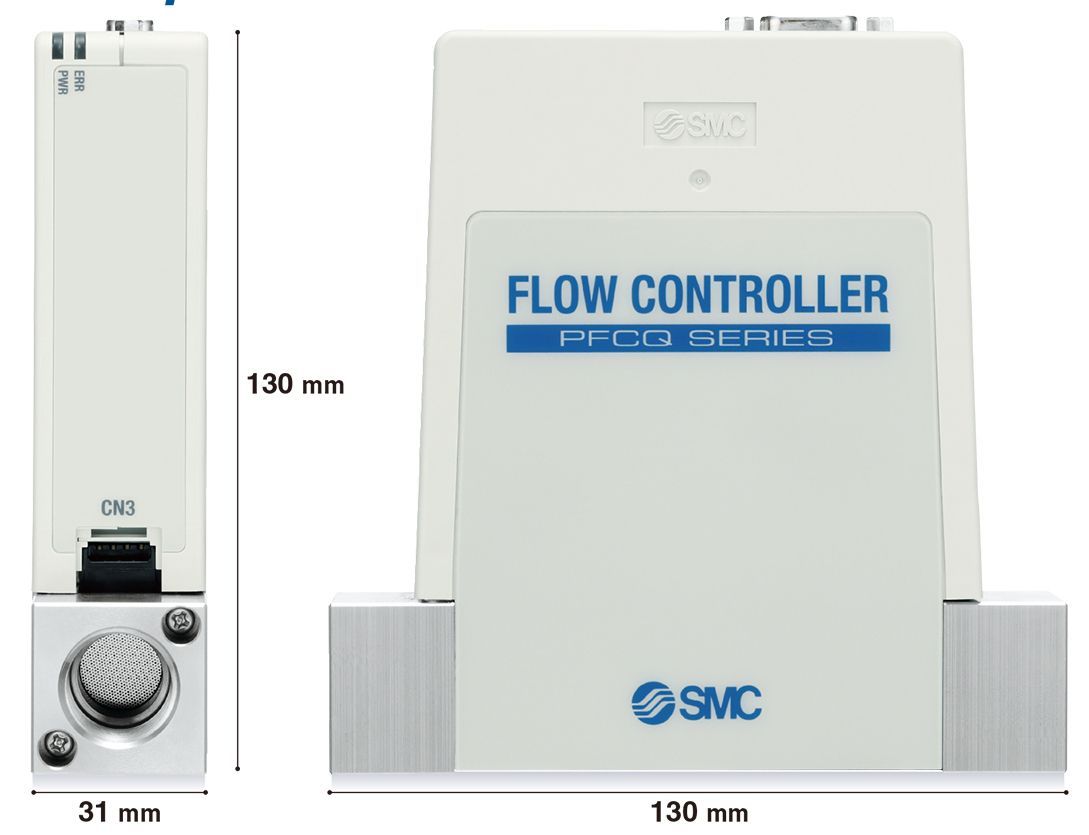

About the PFCQ Series

Designed for clean, compressed air or nitrogen, SMC’s PFCQ Series Flow Controller adjusts the flow automatically in response to an analog voltage or current signal. Highly accurate with 3% Full Scale (FS), this device combines a body, flow sensor, linear motor, valve and electronics to achieve the desired flow rate.

Here’s how the device works. The built-in linear motor changes the valve opening by moving the motor-mounted valve element, thus adjusting the flow rate inside the valve. When the flow rate command signal is input to the controller, the internal operation circuit performs a comparison calculation with the flow rate measured by the sensor. The device then drives the motor based on that value to control the flow rate. When the motor is de-energized, the valve is closed via the attractive force of the permanent magnet mounted to the motor.

The PFCQ features linear control within the rated flow range of 9 to 300 liters per minute. It is grease- and oil-free with no copper or aluminum in the fluid flow path, making it suitable for semiconductor equipment like front-opening unified pods (FOUP) and equipment front-end modules (EFEM). This compatibility helps in maintaining the stringent cleanliness standards required in semiconductor fabrication plants.

In terms of connectivity, the PFCQ is equipped with a D-sub connector for power and input signals. It also supports optional connections to digital flow monitors for enhanced monitoring and control.

Additional features of the PFCQ include:

- A lightweight design — 850 grams

- Pressure range: 0.05 to 0.5 MPa

- Port size: 1/2 Rc

- Power supply: 24V DC

- I/O signal: 1-5V DC or 4-20 mA

- Settling time: ≤ 0.5 seconds

- CE, UKCA and RoHS certified

To learn more about the PFCQ Series Flow Controller, visit

SMC’s website.

“Trust is one of the most important factors when I select a manufacturer. I trust the team at Pearse Bertram to get the job done right and delivered on time.”

-Senior Buyer, Moore Nano

“From time to time, we utilize Pearse Bertram’s engineering team to help us evaluate variables for special applications. It’s nice to have that value-add service.”

-Supply Chain Manager, MP Systems

“Pearse Bertram has been a great partner over the years ---they’ve been very responsive to our needs to manufacture and trouble shoot production issues.”

-Design Engineer, Marubeni Citizen Cinco

“Trust is one of the most important factors when I select a manufacturer.

I trust the team at Pearse Bertram to get the job done right and delivered on time.”

-Senior Buyer, Moore Nano

“From time to time, we utilize Pearse Bertram’s engineering team to help us

evaluate variables for special applications. It’s nice to have that value-add service.”

-Supply Chain Manager, MP Systems

“Pearse Bertram has been a great partner over the years; they’ve been

very responsive to our needs to manufacture and troubleshoot production issues.”

-Design Engineer, Marubeni Citizen Cinco